Plastic injection moulding

Specialist in plastic injection moulding

The injection moulding of thermoplastics is a profession in its own right. Injection moulding company CKV Plastics has over thirty years of experience in injection moulding small components. We manufacture any shape and any size: from 0.5 to 500 g and with a closing force of 250 to 3000 kN! .

Strong in TPEs

Ever since the early emergence of thermoplastic elastomers, we have been moulding these materials and gathered the knowledge of the different materials in-house. From SBS caps to TPEE chair legs, anything is possible with these flexible materials. . .

.

. . .

Questions or more information?

contact us

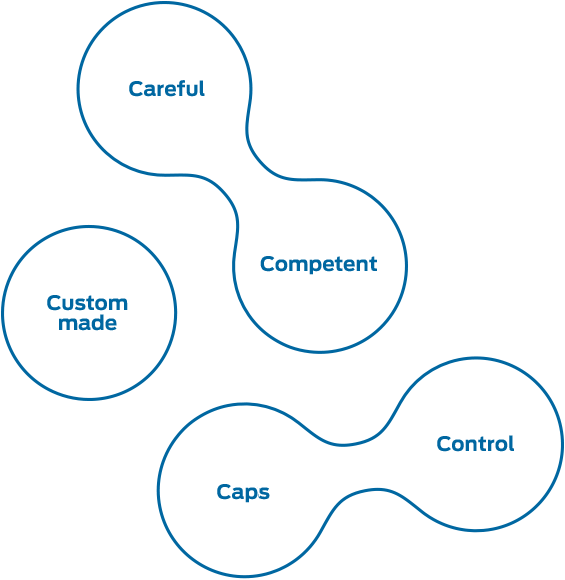

The 5 Cs of CKV Plastics

What can you expect from CKV?

Bij CKV Plastics kunt u vertrouwen op kwaliteit. Wij passen kwaliteit toe in al onze activiteiten en dit komt tot uiting in onze producten. Om u kwaliteit te garanderen, werken wij met vijf speerpunten, Careful, Competent, Custom made, Caps en Control. Lees hier meer over onze speerpunten en de betekenis ervan!

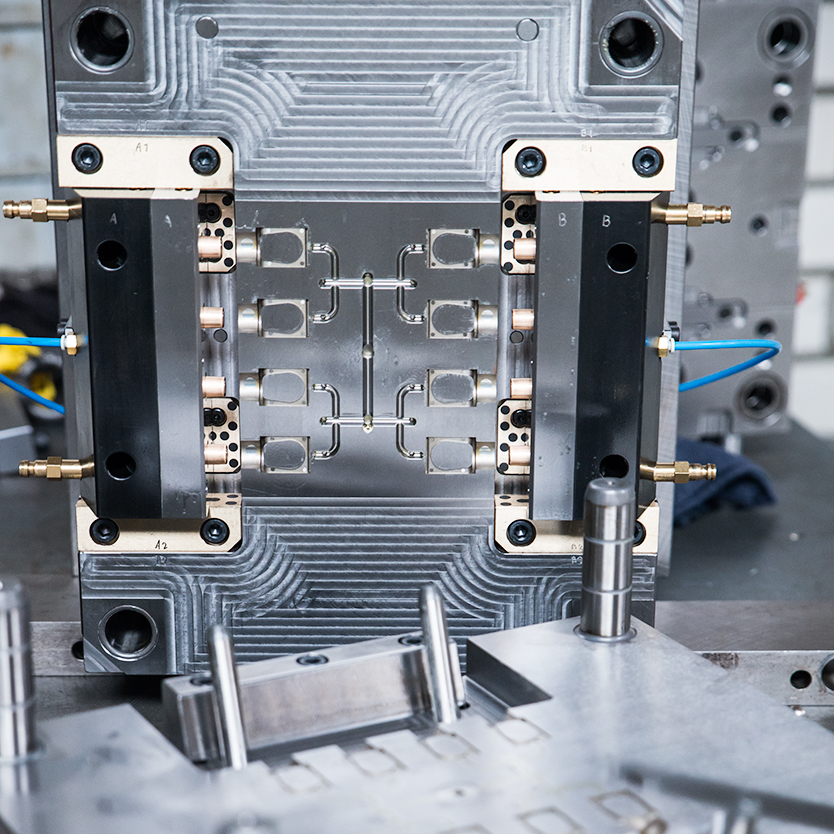

A good mould as a base

The mould is the most important and most expensive part of the injection moulding process. At CKV Plastics, we work with experienced mould-makers who deliver serious craftsmanship, every single time. The quality of their moulds translates into perfect products, faster cycles and lower maintenance costs.

CONTACT US

Questions or more information?

More than 30 years experience

CKV Plastics has been a specialist in the injection moulding of plastic products ever since 1983. Our expert employees work hard every day to manufacture a wide variety of plastic products.

Quality thinking

From an efficient production process to the provision of excellent products: quality can be found in all facets of our business.

State-of-the-art machinery

CKV Plastics works with the latest machinery that can do many different things.

Personal attention

Short lines and personal contact is crucial for the success of your project.